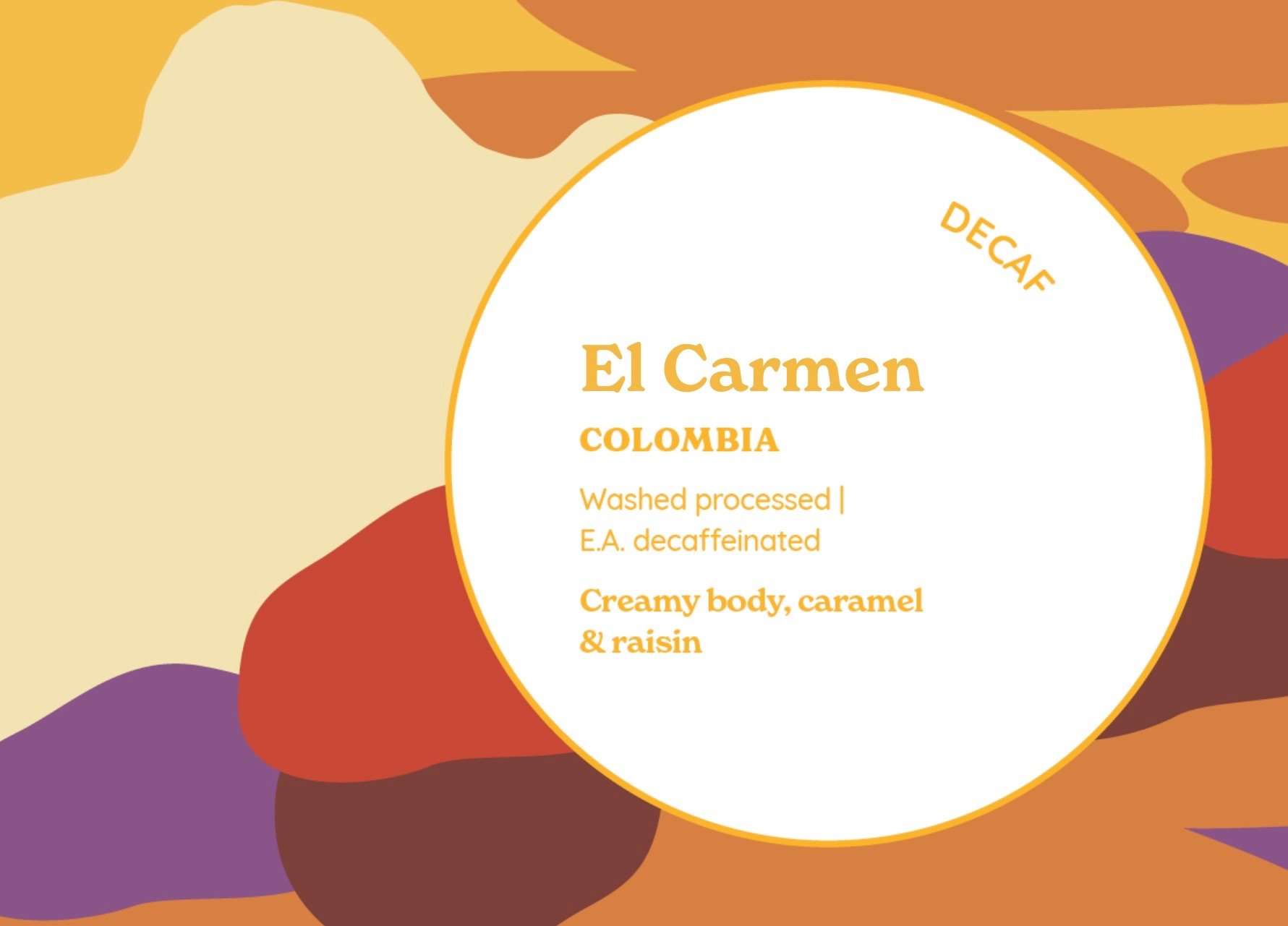

Decaf: El Carmen | Colombia

Key Origin Info:

Producer: Small producers, members of El Carmen de Acevedo Associaition

Processed at: each farmer’s wet mill and consolidated in dried parchment stage before being decaffeinated at a facility in Manizales

Region: Huila

Altitude: 1400 - 2100 masl

Variety: Mixed, mostly Caturra, Castillo & Colombia

Process: Washed processed and E.A. “Sugarcane” decaffeinated

Exporter: Raw Material | Importer: Raw Material

Cup profile: Creamy body, caramel & raisins

About El Carmen:

This community lot has been grown and processed by small producers of the El Carmen association in Pitalito, Huila. El Carmen de Acevedo Association is part of the Red Associations project by Raw Material (our importing partner) the aim of which is to improve infrastructure and achieve stable and profitable prices for the groups’ coffees through improved quality control, knowledge sharing and access to the speciality market.

The launch of the project and associated work followed an initial meeting in 2017 where the Raw Material team spoke with producers association in the area to learn what the challenges are and offer solutions. The main challenge was the lack of key infrastructure and un-stable and often unprofitable prices which disable any investments in improved quality. Together, they also uncovered a wide gap between how the quality is discussed and measured at the farm level.

To overcome these challenges a new drying bed facilities and QC infrastructure were built at the community central hub in the town of El Carmen. Additionally, a new payment system was put in place where individual farmers are paid a stable minimum price for a unit of dry parchment coffee they produce through a community lot of base speciality quality standard. This price results in over double the household income of a typical coffee producing family, compared with the average income in the regular market over the past 5 years. With increases in producers’ cost of production this pricing needs to be continuously reviewed to ensure continued.

More about the “Sugarcane” decaffeination process:

Also known as E.A. - “ethyl acetate” decaffeination is a natural process that not only maintains great integrity of green-coffee flavour, but also allows us to offer a decaffeinated coffee that best supports a vertical supply chain. This is due to the fact that the growing, processing, and even the full decaffeination process all happens at the source in Colombia, meaning all value added by these processes stays within the country of origin and its communities.

How does it work:

The washed and dried green coffee is received at the decaffeination plant and it is steamed for approx. 30 minutes. A low-pressure steaming process opens the pores of the coffee, allowing for caffeine extraction.

Coffee is placed in a solution of water and Ethyl Acetate (E.A.), a naturally occuring compound and solvent derived through the fermentation of sugarcane. While submerged in the solvent, E.A. naturally bonds to the salts of chlorogenic acids within the coffee, allowing for the extraction of caffeine.

Once the solvent is saturated, the tank is drained and fresh solution is introduced. This continues for about 8 hours.

After the last of the caffeine has been extracted, the coffee is removed from the solution and prepped for another steaming. The final low-pressure steaming removes the remaining traces of E.A.

Decaffeinated coffee is then dried, physically polished to ensure cleanliness, and packaged for export.